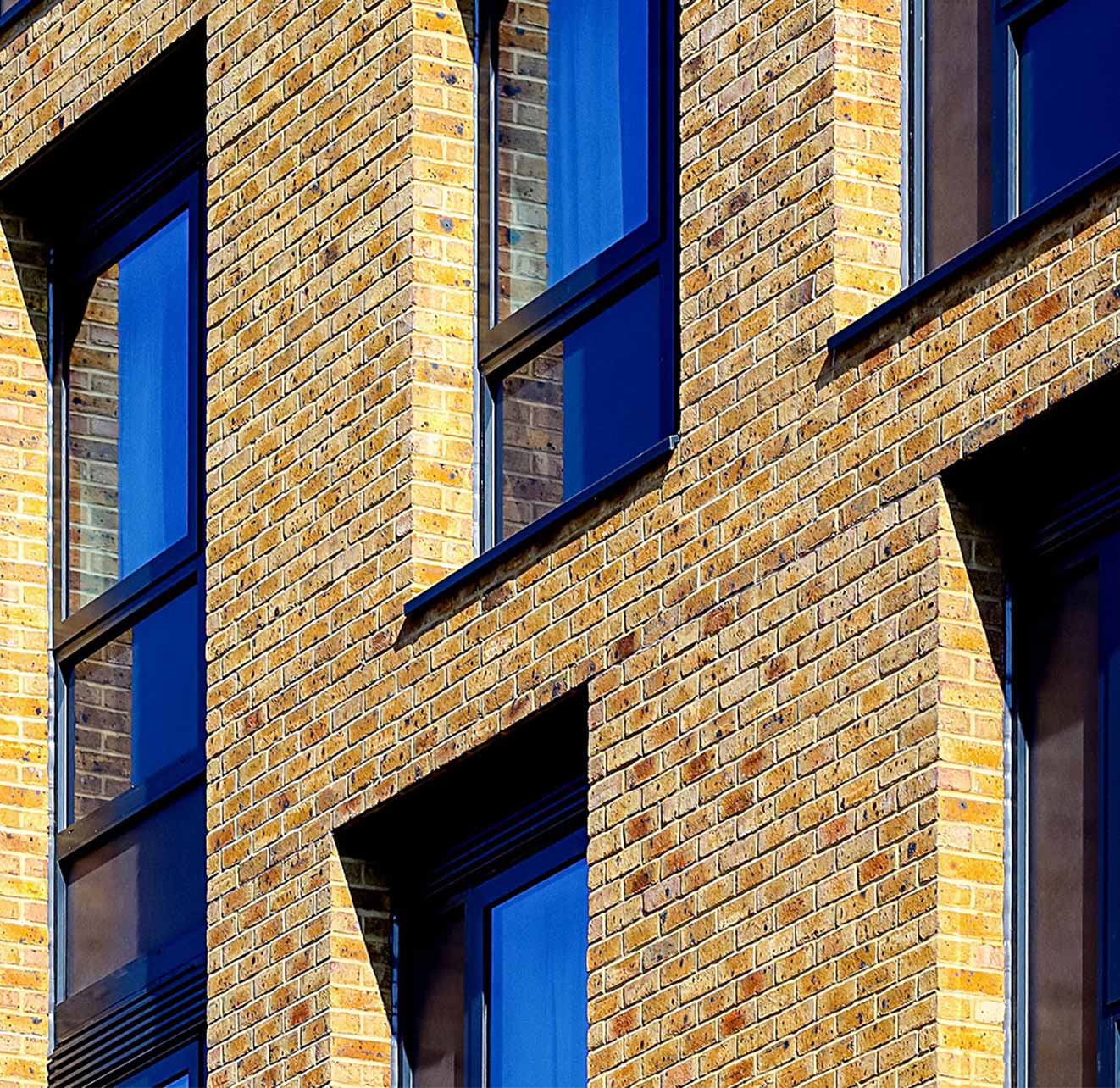

Our 75,000 square foot production facility is where precision is made.

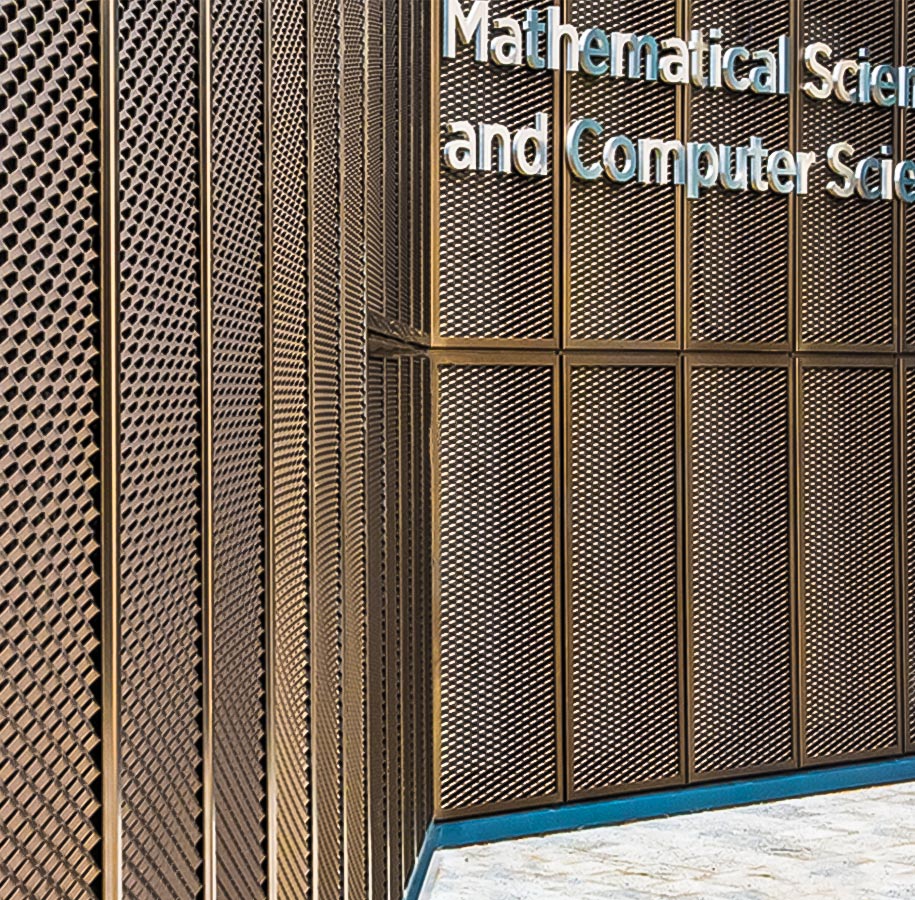

At Proteus, we combine advanced technology with skilled craftsmanship to deliver precise, high quality façade solutions.

Our facility is equipped to handle projects of any size. From large production runs to bespoke one-off fabrications we work with a range of materials to meet the unique demands of each project. With full in-house control we manage every stage from initial design through to prefinished installation ready systems ensuring accuracy, consistency and a flawless finish.

Our efficient setup and adaptable processes enable us to meet tight deadlines without compromising on detail giving clients confidence in both our quality and reliability.

Our Manufacturing Facility

We combine a state of the art facility, advanced machinery, and smart manufacturing processes to deliver precision engineered solutions.

-

Our 75,000 sq ft facility in Skelmersdale includes two large production halls and an external storage building, giving us the capacity to handle everything from bespoke fabrications to high-volume projects. By keeping operations in-house we maintain complete control over quality, accuracy and turnaround times. This setup allows us to respond quickly to project needs while upholding the highest standards throughout production.

-

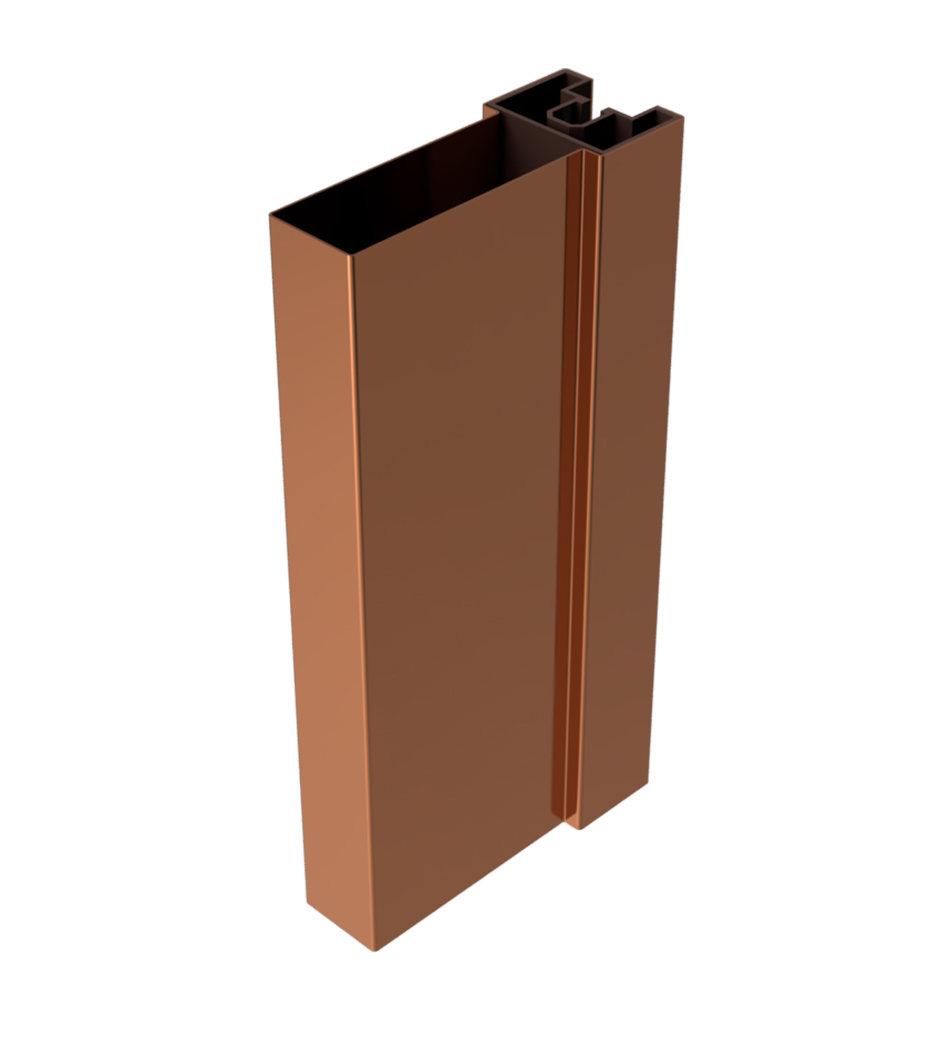

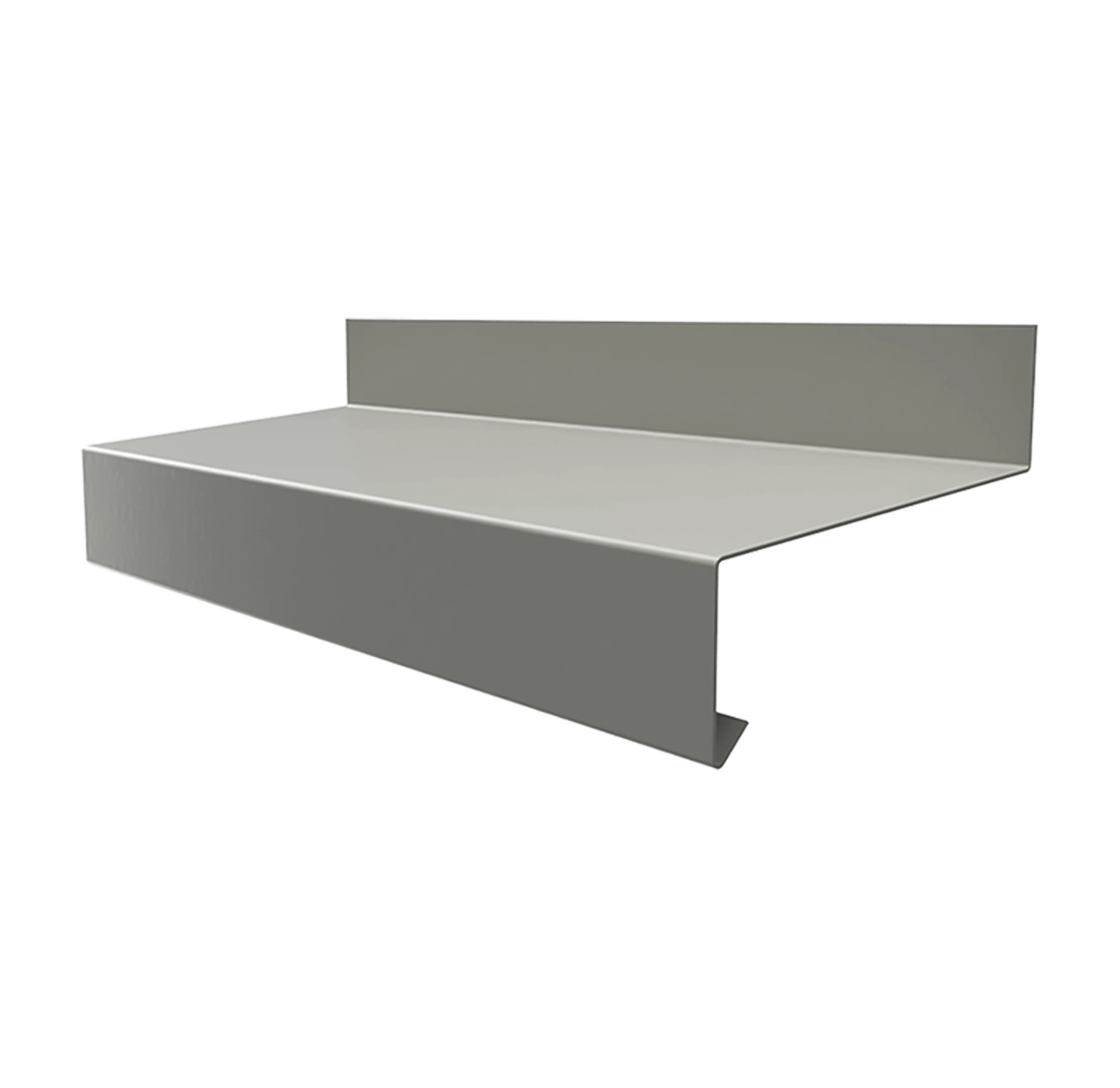

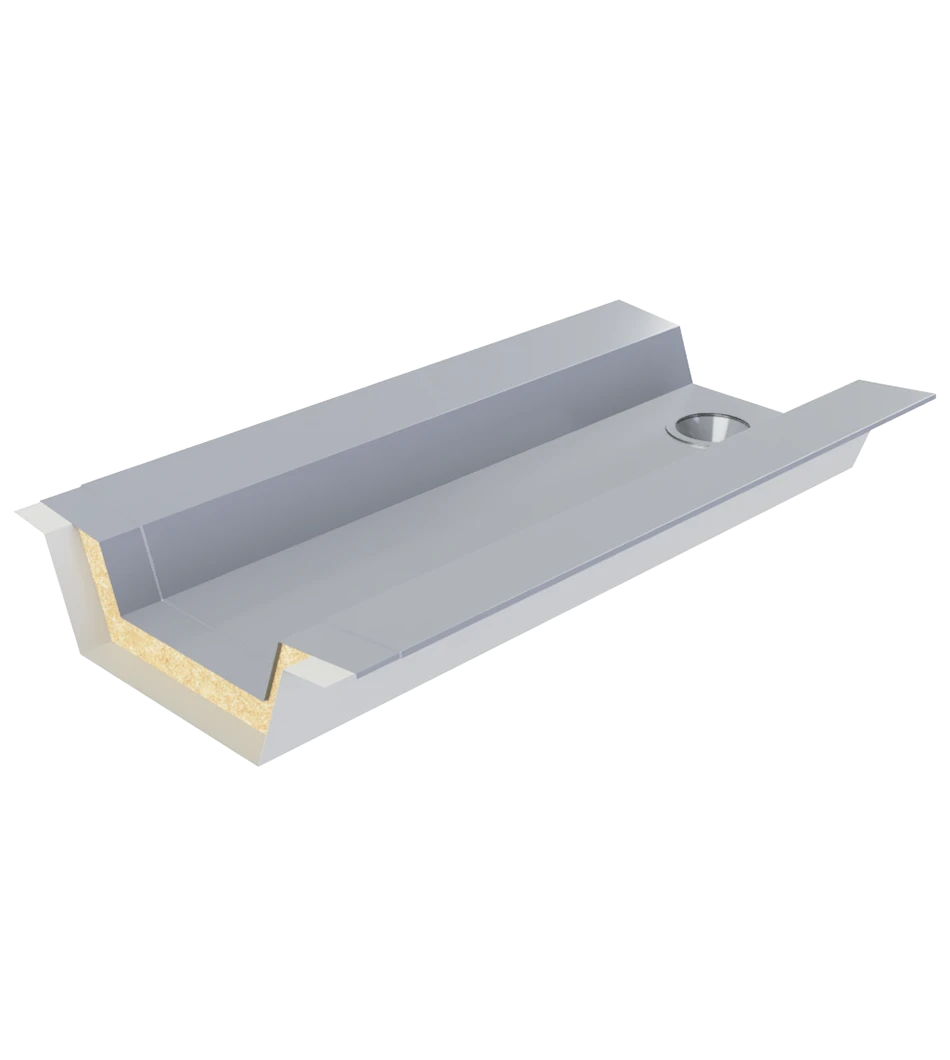

We have invested in a wide range of machinery to manage projects of all sizes. From CNC machines to press brakes, punches, laser cutters, guillotines, rollers and saws everything is designed for precision and efficiency. We also operate a dedicated gutter manufacturing line and other specialised equipment to provide bespoke solutions tailored to specific project requirements.

With the capacity to manufacture up to 55,000 square metres annually our machinery supports large-scale projects without compromising quality. Our 10,000 square feet of storage space and dedicated welding bays give us both the capacity and expertise to take on any project, big or small.

-

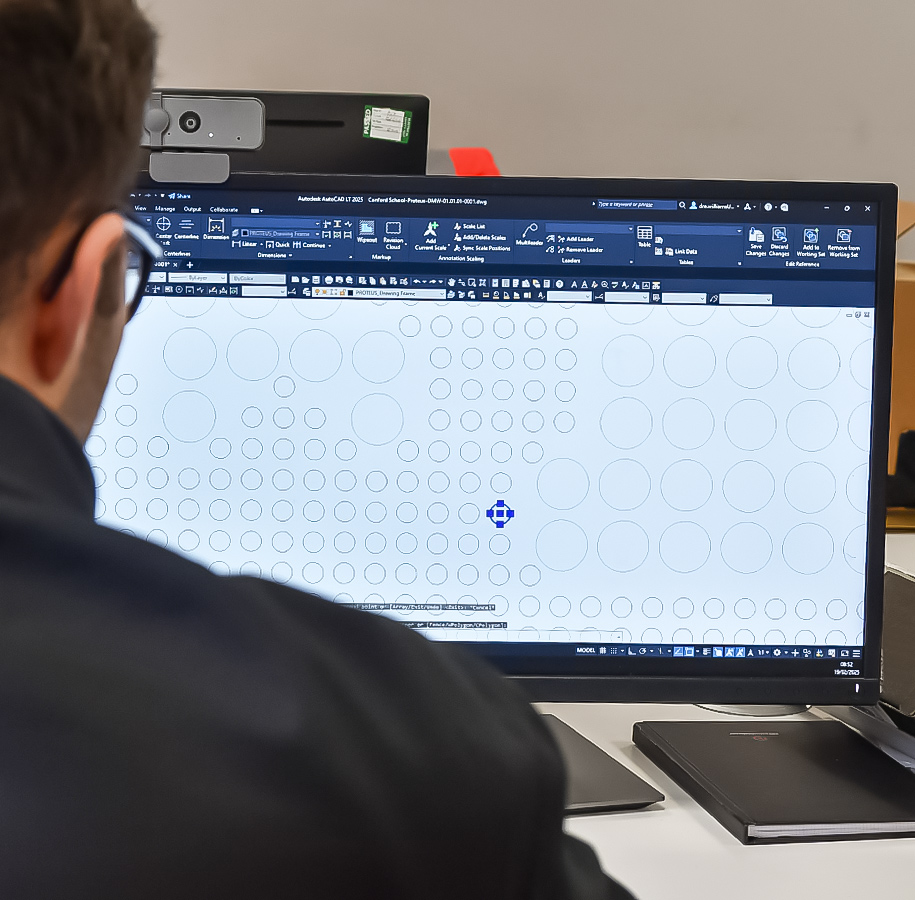

At Proteus we use leading CAD software including Radan, AlphaCam, Revit, Inventor, AutoCAD and Bendex to ensure precision and efficiency across everything we produce. We keep up with emerging technologies by attending key industry events such as the GRAITEC convention.

Our software is fully integrated with our production line, enabling seamless communication between the design team and manufacturing. Once designs are finalised our team programs the machines to support a smooth controlled workflow from start to finish. This integration reduces lead times, improves accuracy and ensures consistently high quality results for every project.

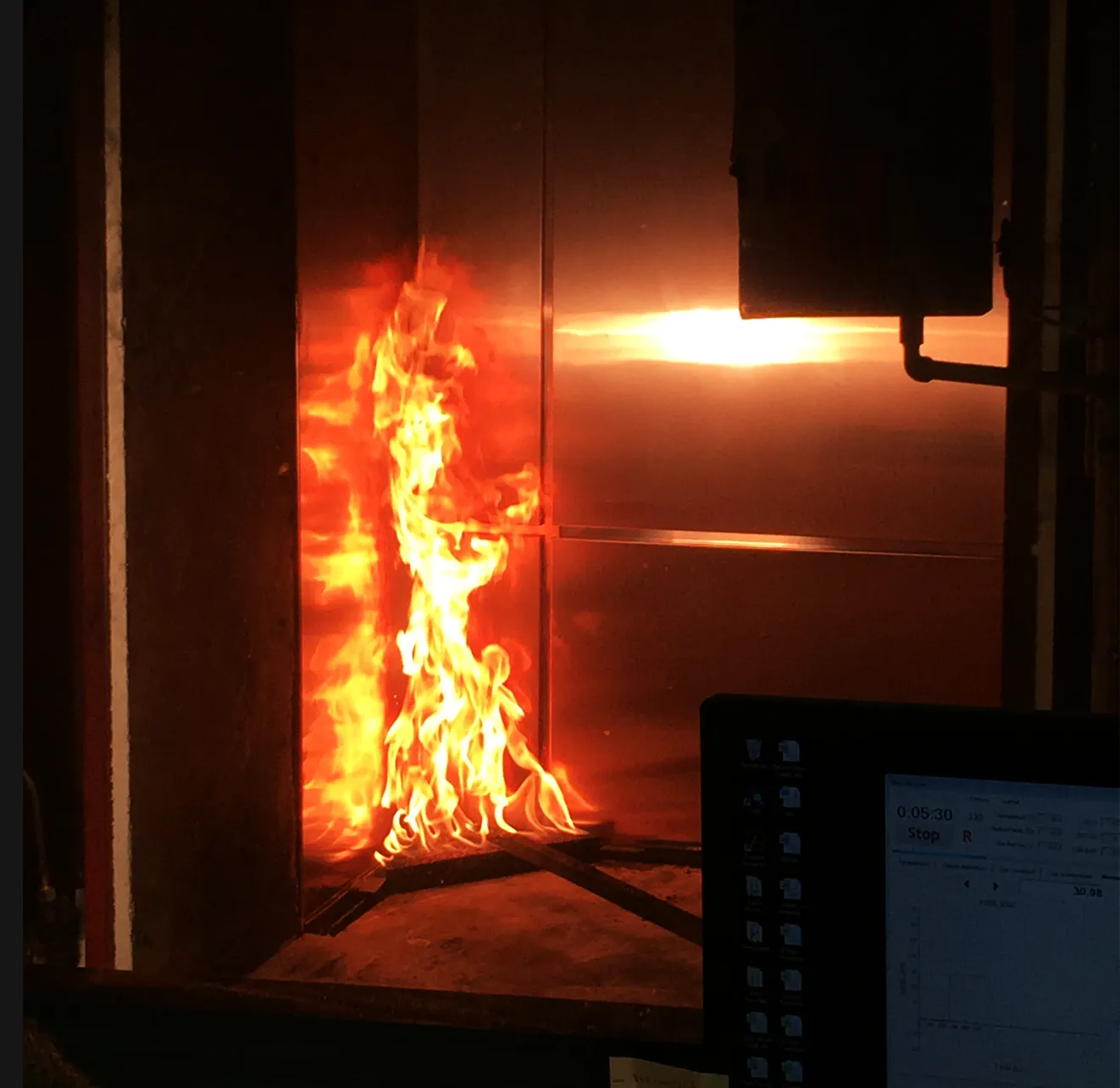

Assured Safety & Compliance

We uphold the highest standards of quality and safety, ensuring every project meets our commitment to excellence and reliability.

-

Proteus holds ISO 9001:2015 and ISO 14001:2018 certifications, demonstrating that our processes meet high standards of quality, safety and environmental management. These accreditations support efficiency, strong health and safety practices, and responsible waste management. Quality control remains a priority, with strict inspections ensuring every product meets exacting standards. Our ISO 45001 certification further reflects our commitment to maintaining a safe, well-managed working environment.

We ensure compliance through regular audits, ongoing training and continuous improvement. Feedback from our team plays a key role in refining our processes and maintaining high standards.

-

Building Information Modelling (BIM) delivers significant value to architects, contractors, and manufacturers. It is more than just 3D CAD or the latest technology; BIM enables collaboration throughout the entire project lifecycle, enhancing efficiency and reducing errors.

At Proteus, we provide Level 2 BIM models for all our systems, available for direct download from our website. This offers clients access to the most accurate and up-to-date project information. Our models comply with the UK’s COBie UK 2012 standards, ensuring alignment with current industry requirements.