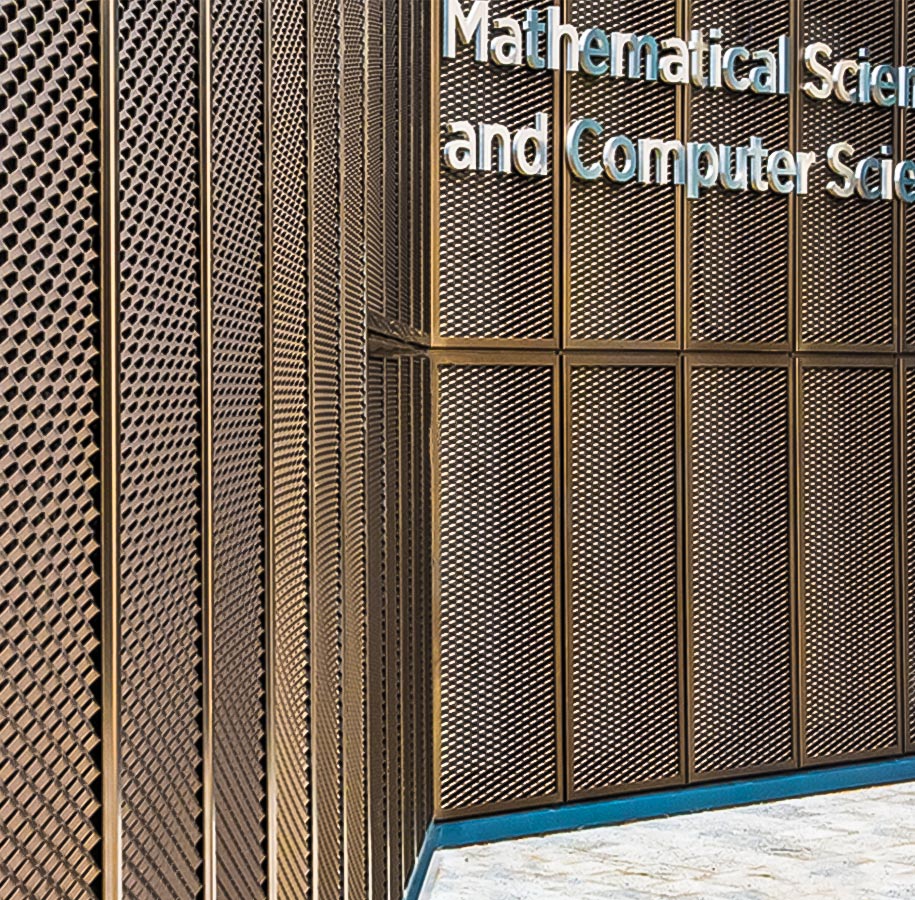

The ICT Papermill in Deeside marks a bold new chapter in North Wales’ industrial future. Situated on a 50-acre site within the Northern Gateway, a major redevelopment of the former RAF Sealand.

This state-of-the-art facility is being developed by Italian paper manufacturing giant Industrie Cartarie Tronchetti (ICT). Once operational, it is set to generate over 400 jobs and significantly reduce the UK’s reliance on imported tissue products, addressing a domestic production gap estimated at over 340,000 tonnes annually. As part of this landmark development, The H2Pro insulated gutter system was specified to support the mill’s rainwater management strategy.

Spanning more than 32,000 linear metres in total, the system plays a critical role in the building’s performance, delivering reliable drainage while contributing to thermal efficiency across the envelope. Each component was designed with speed, durability and ease of installation in mind, combining high-volume manufacturing with precise, controlled fabrication.

Project Details

- Sector: Commercial

- Systems: H2Pro

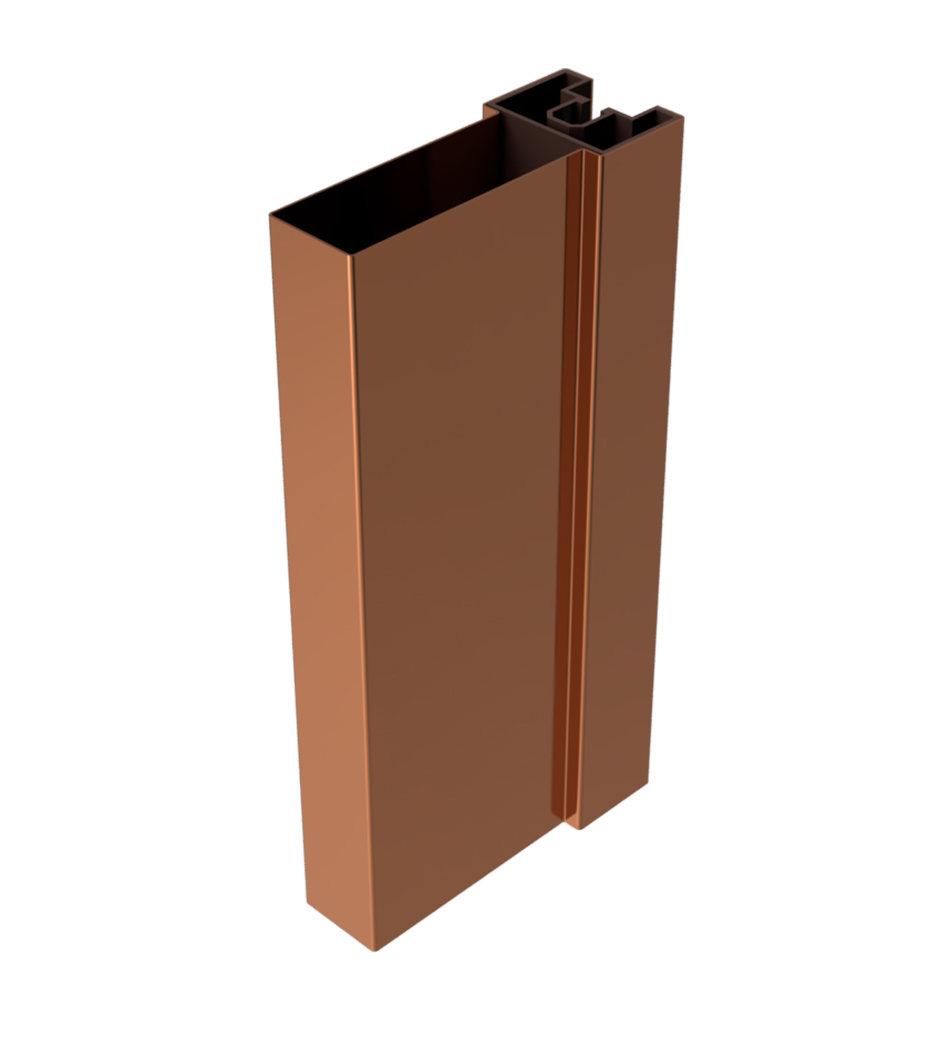

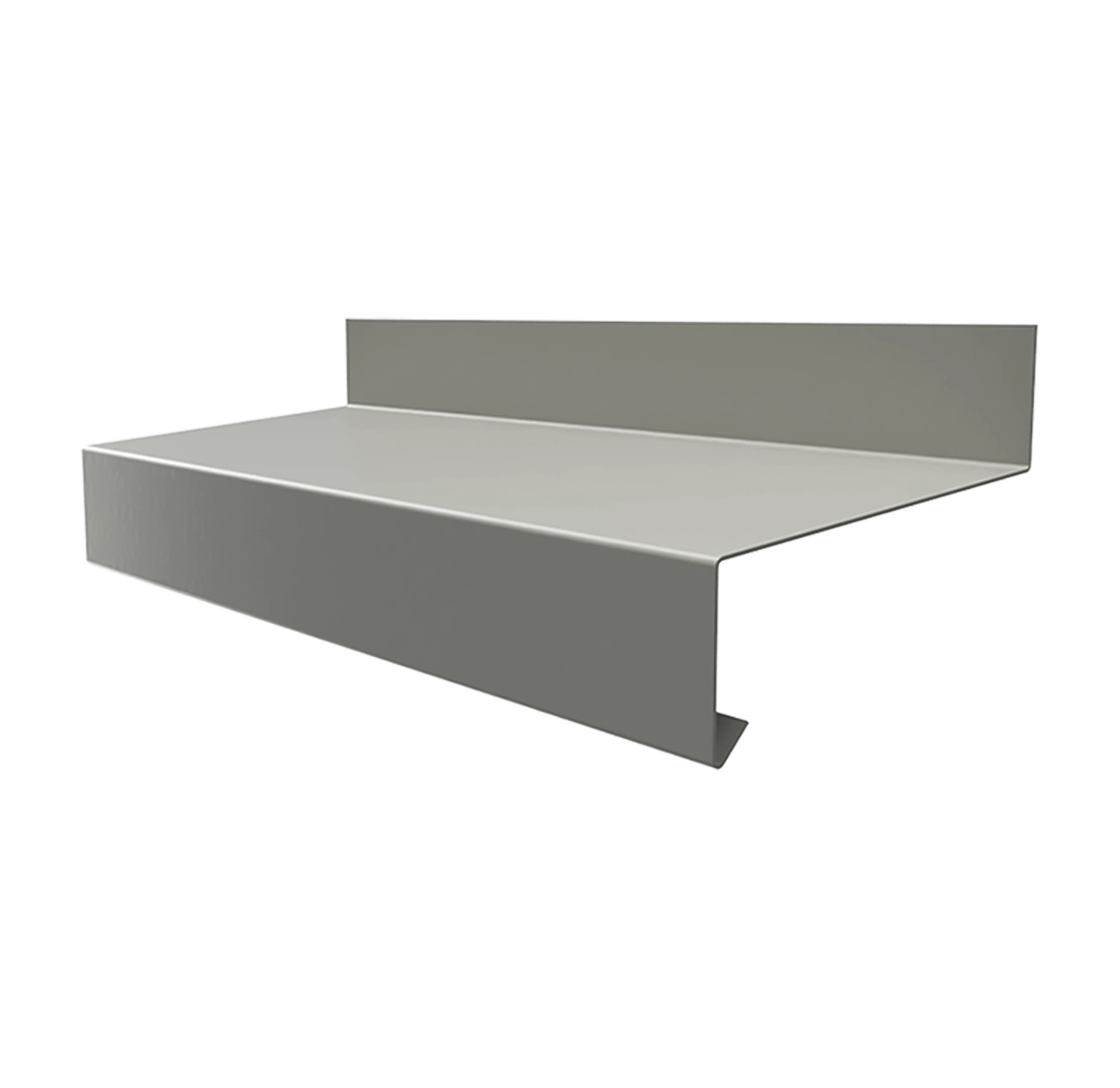

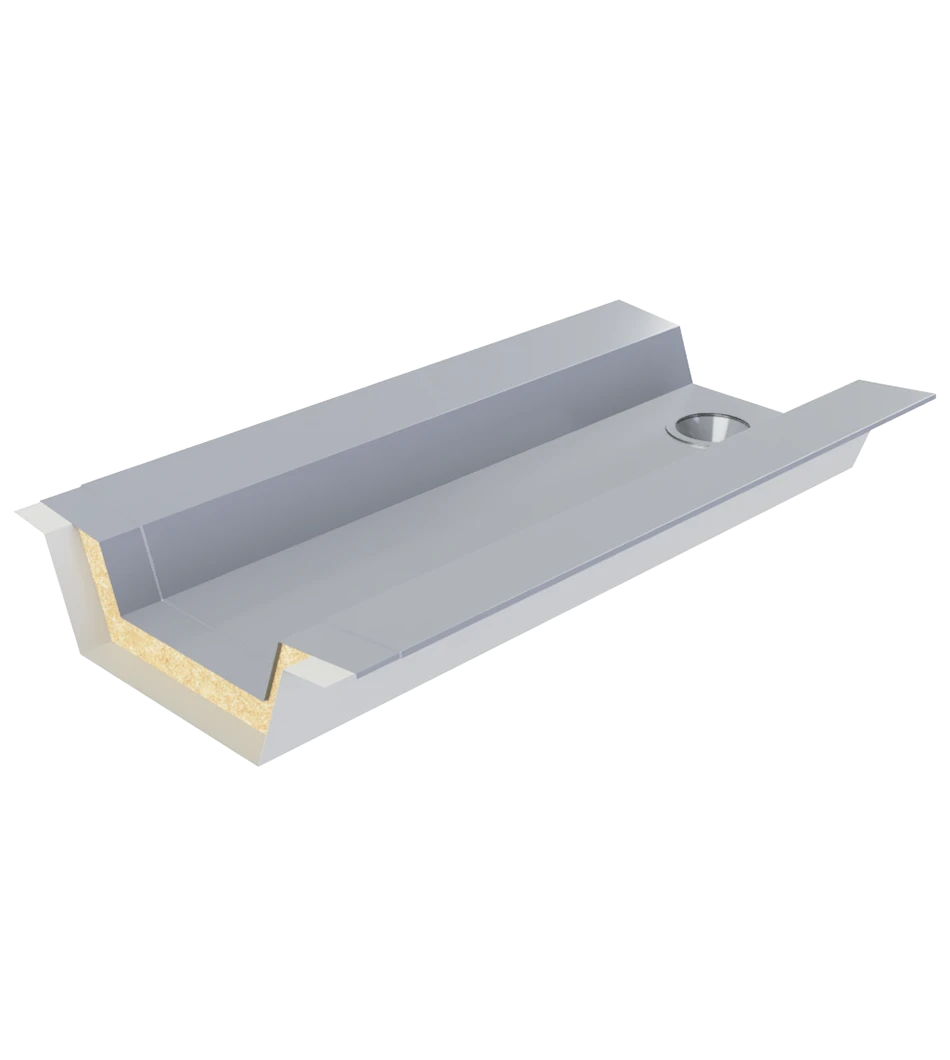

The H2Pro insulated gutters were manufactured using 50mm PIR insulation and lined with Fatra (Raintite), a proven waterproofing membrane known for its durability and long-term performance. We manufactured a full range of standardised components, including boundary gutters, valley sections, corners and T-junctions, each element was carefully fabricated to work and integrate seamlessly with the roof design and cladding system, ensuring uniformity, reliability and fast-paced installation on-site.

Northern Cladding led the installation, with crane lifts made possible by integrated lifting eyes that had been incorporated into every gutter. This enabled safe, efficient handling and eliminated the need for temporary lifting solutions. Delivered in sequence and fully prepared for installation, the gutters were ready to slot into place as the build progressed northwards, allowing cladding teams to maintain momentum across a busy site.

Factory-welded joints further streamlined the process, reducing site labour while removing the risks associated with cold-applied seams.

The result was a consistent, watertight system that will require minimal maintenance and continue to perform long into the future. Combined with its thermal insulation and durable liner, the system supported the wider environmental goals of the project, contributing to flood risk mitigation, air quality compliance and broader regulatory objectives tied to sustainable construction.

Though just one part of this transformative development, the gutter system reflects the value of precision manufacturing, efficient installation, and product reliability at scale. Delivered on time and installed with minimal disruption, it stands as a small but significant contributor to one of the UK’s most exciting industrial builds. As the ICT Papermill prepares for operation, we are proud to have played a role in supporting its success with systems engineered for performance, longevity and ease of use.